College of Engineering

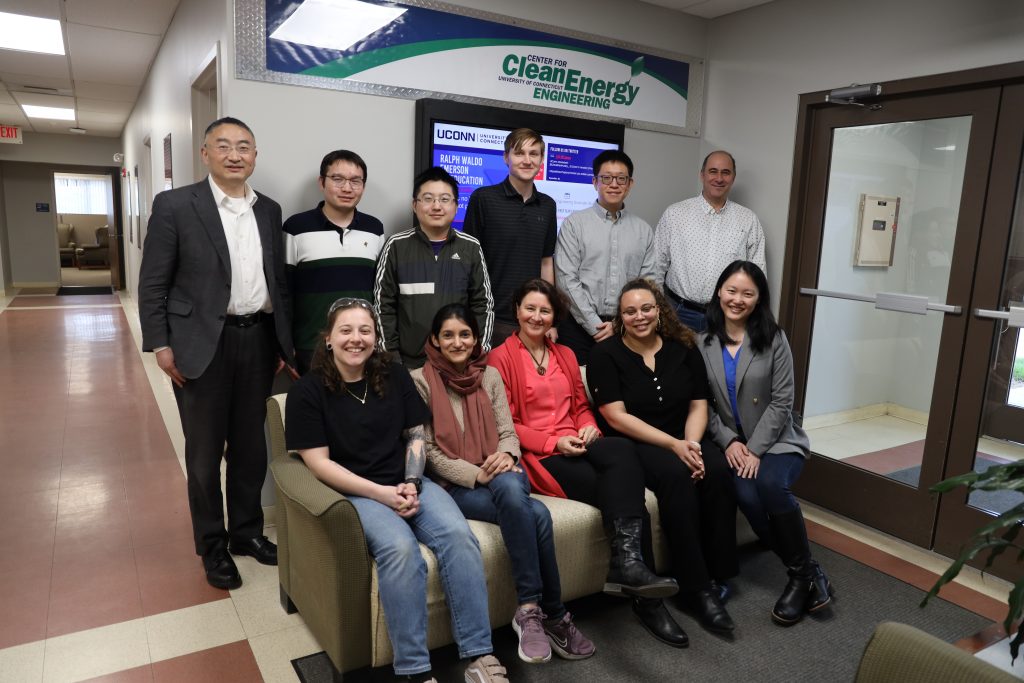

DOE Grants Fund Collaborative Clean Energy Projects

UConn is one of dozens of beneficiaries in funding program to bolster research into hydrogen energy and related projects

April 25, 2024 | Matt Engelhardt

UConn Provost Announces Awards for Excellence in Community Engaged Scholarship

The Provost’s Awards for Excellence in Community Engaged Scholarship (PAECES) recognize scholarly activities that integrate community engagement with research, creative work, and teaching

April 24, 2024 | Briana Huett, Associate Director of Outreach and Engagement

Pratt & Whitney Engineering Building Unveiled

Pratt & Whitney has strong ties to the UConn College of Engineering and UConn School of Mechanical, Aerospace and Manufacturing Engineering

April 22, 2024 | Claire Tremont

College of Engineering Names New Dean

Ji-Cheng ‘JC’ Zhao brings 30 years' experience working in academia, industry, and government

April 19, 2024 | Claire Tremont

Six UConn Faculty Members Named AAAS Fellows

The AAAS is the world’s largest general scientific society and publisher of the Science family of journals

April 18, 2024 | Mike Enright '88 (CLAS), University Communications

Meeting the High-Speed Challenge

The Air Force Research Laboratory awarded UConn an additional $10.5 million for projects related to welding and advanced materials for high-temperature applications

April 18, 2024 | Matt Engelhardt

UConn Celebrates Promotion and Tenure of 91 Faculty

Evaluations for promotion, tenure, and reappointment apply the highest standards of professional achievement in scholarship, teaching, and service for each faculty member evaluated

April 17, 2024 | Alexis Lohrey, Office of the Provost

Shining Light Makes Materials Magnetic at Room Temperature

In April, Engineering Professor Alexander Balatsky published his work applying AI to his theory of 'dynamic multiferroicity'

April 17, 2024 | Christie Wang, for the Office of the Vice President for Research

Engineering Entrepreneurship: Hacking For Defense

The course uses a project-based approach to get students out of the classroom and into the community, engaging with defense industry professionals

April 16, 2024 | Claire Tremont

UConn Leading Federally Backed Regional Initiative to Defend Electric Grid from Cyberattack

CyberCARED will take UConn’s cybersecurity research and development into a new domain

April 9, 2024 | Jaclyn Severance