College of Engineering

Six UConn Faculty Members Named AAAS Fellows

The AAAS is the world’s largest general scientific society and publisher of the Science family of journals

April 18, 2024 | Mike Enright '88 (CLAS), University Communications

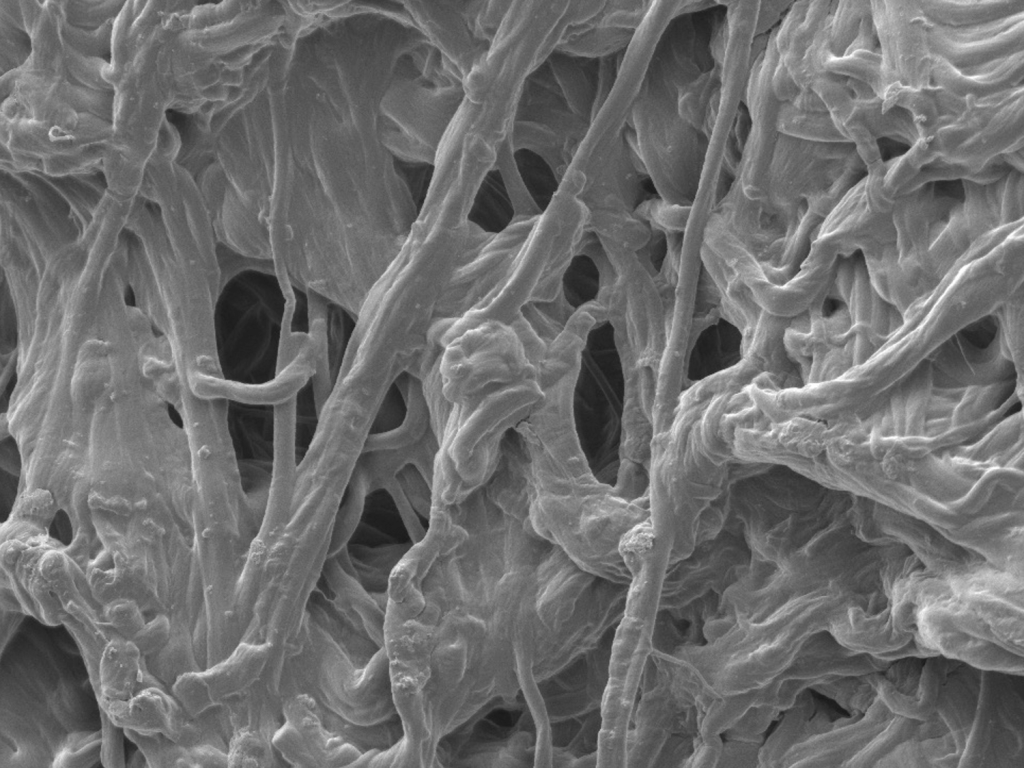

Meeting the High-Speed Challenge

The Air Force Research Laboratory awarded UConn an additional $10.5 million for projects related to welding and advanced materials for high-temperature applications

April 18, 2024 | Matt Engelhardt

UConn Celebrates Promotion and Tenure of 91 Faculty

Evaluations for promotion, tenure, and reappointment apply the highest standards of professional achievement in scholarship, teaching, and service for each faculty member evaluated

April 17, 2024 | Alexis Lohrey, Office of the Provost

Shining Light Makes Materials Magnetic at Room Temperature

In April, Engineering Professor Alexander Balatsky published his work applying AI to his theory of 'dynamic multiferroicity'

April 17, 2024 | Christie Wang, for the Office of the Vice President for Research

Engineering Entrepreneurship: Hacking For Defense

The course uses a project-based approach to get students out of the classroom and into the community, engaging with defense industry professionals

April 16, 2024 | Claire Tremont

UConn Leading Federally Backed Regional Initiative to Defend Electric Grid from Cyberattack

CyberCARED will take UConn’s cybersecurity research and development into a new domain

April 9, 2024 | Jaclyn Severance

UConn’s Engineers Without Borders Hosts Northeast Regional Conference

Students learned how other EWB chapters in the Northeast are helping communities around the world solve problems

April 3, 2024 | Olivia Drake

Graduate Students Share Research, Network with Peers at UConn’s Sustainability Summit

The inaugural summit, hosted by the College of Engineering's Center for Clean Energy Engineering (C2E2), brought together students from various disciplines within C2E2 and across at least five engineering departments and schools

April 2, 2024 | Jordan Baker

Gift of Fuel Cell Units Enhances UConn’s Clean Energy Commitment

Eight solid oxide fuel cell units will be donated to the Center for Clean Energy Engineering

April 2, 2024 | Matt Engelhardt

Professor Receives a $3M RO1 Grant From the National Institutes of Health

The research conducted at the UConn College of Engineering is poised to make significant contributions to the field of biomechanics and improve human health outcomes in the process.

March 29, 2024 | Joanna Giano